Pharmaceutical 3D Printing for Personalised Medicine

FABRX provides pharmaceutical 3D printers, software, and pharma-ink development services for personalised medicine and small batch manufacture, ideal for drug development and clinicals trials.

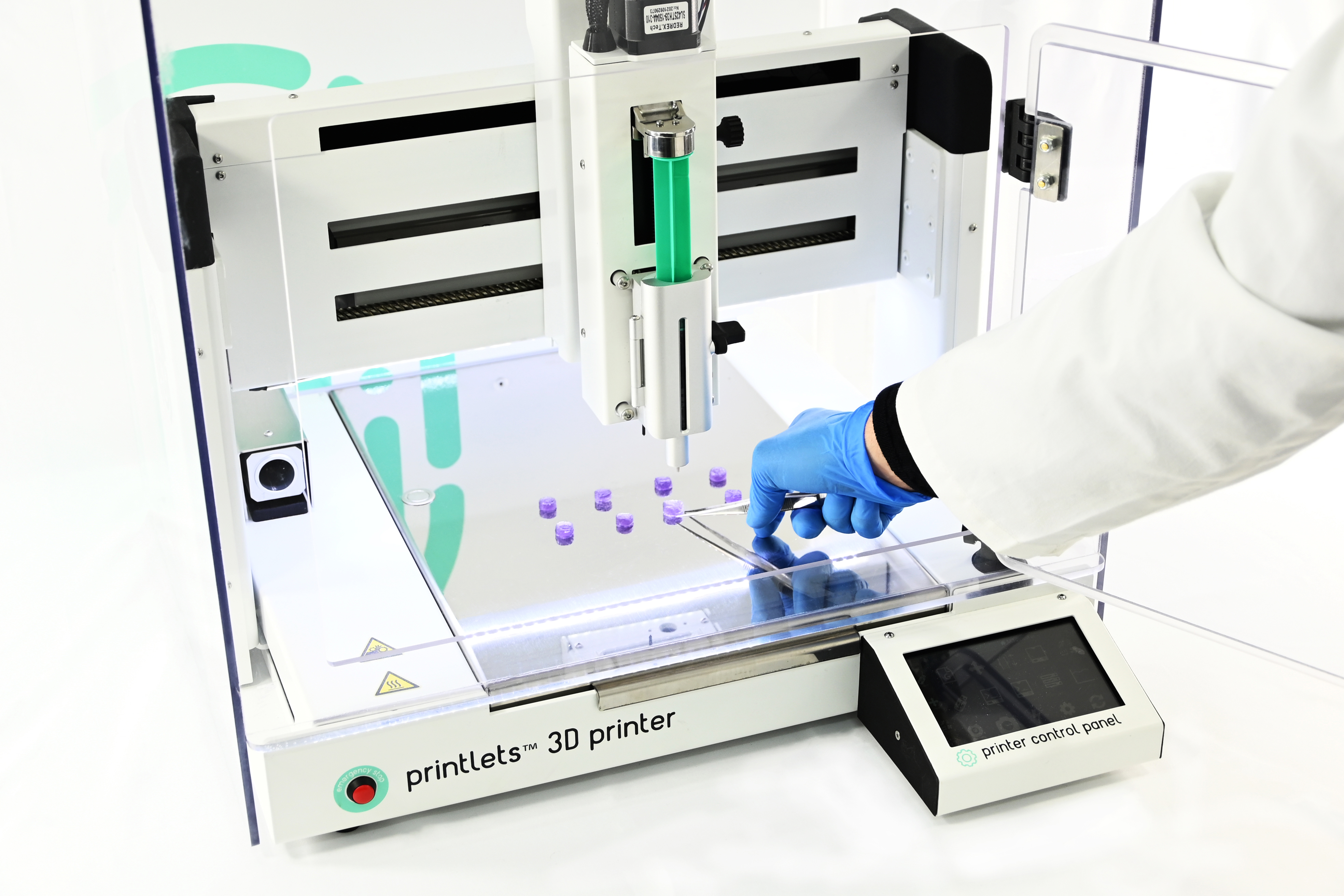

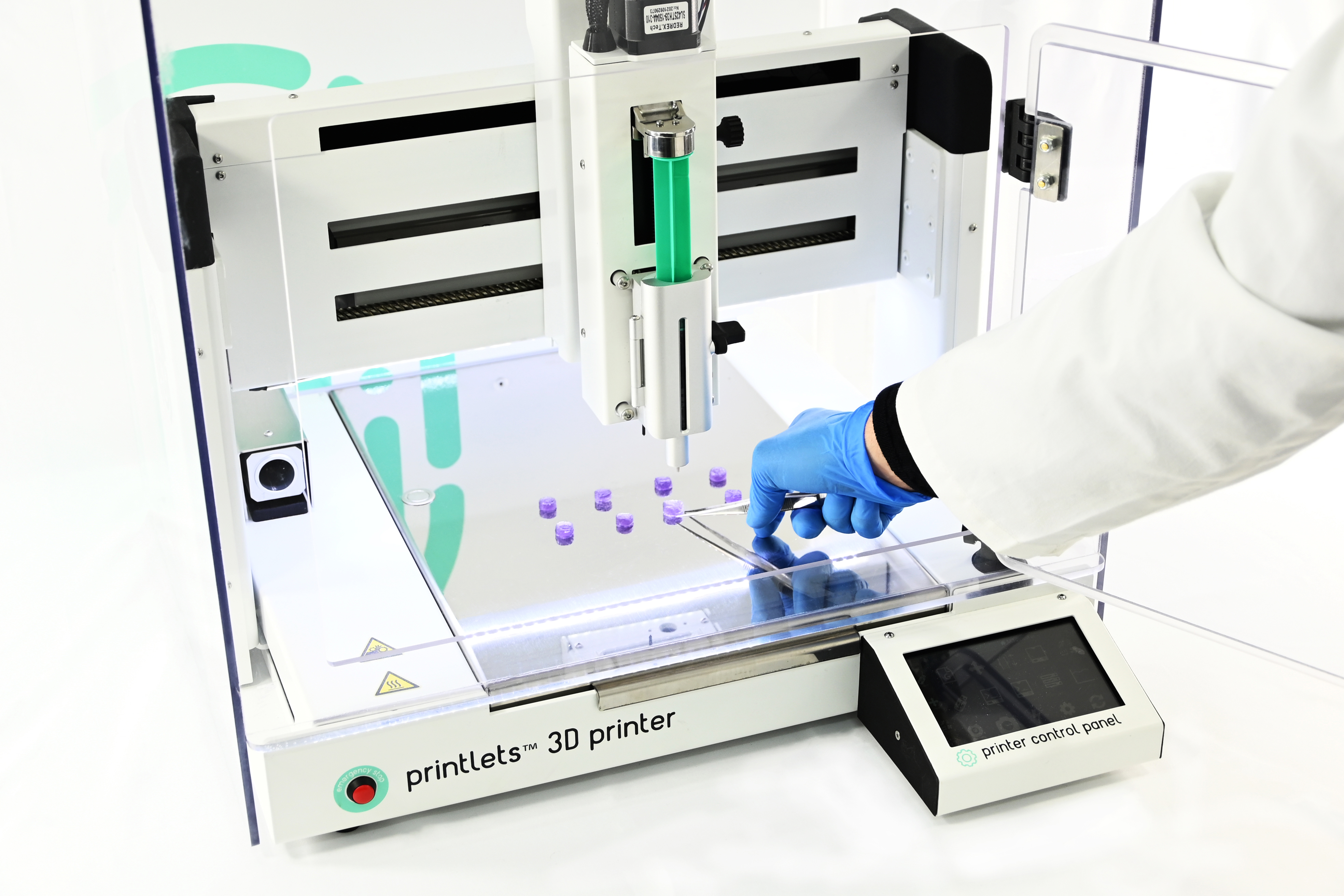

Pharmaceutical 3D Printer

The M3DIMAKER is the world's first GMP-ready pharmaceutical 3D printer series with in-built quality control features and exchangeable printheads for fully personalised human and veterinary precision medicine manufacture.

Our printers can be used under extemporaneous/compounding preparation regulation using standard pharmaceutical excipients. Available to purchase or rent.

Software

Personalised prescriptions with just a few button clicks; our comprehensive, easy-to-use M3DIMAKER Studio software packages can be used to control the printer, ensure quality and collect patient feedback, providing simplified workflows and data management.

Printlets™ & Pharma-inks

Our world leading scientists can help you design, develop and test 3D printable pharma-inks for your chosen active ingredients, as well as manufacture small batches of novel medication for clinical trials.

Research & Pharma-ink development

FABRX is involved in a number of projects for personalised medicine with hospitals, universities and pharmaceutical companies. In the next few years, we will have hundreds of pharma-ink protocols that can be implemented into compounding workflows for a range of drugs and treatment pathways, to be prepared by the pharmacist or supplied as pre-filled cartridges for simplified workflows. Below is a pipeline reflecting some of our current projects in a variety of disease and therapeutics areas.

Early Stage

Formulation Development

Preclinical Stage

Clinical Stage

Oncology

Rare diseases

Metabolic disorders

Transplants

Nutraceuticals

Research

FABRX is involved in a number of projects for personalised medicine with research organisations, universities and pharmaceutical companies to develop novel dosage forms using pharmaceutical 3D printing. Below is a pipeline of our current projects in a variety of disease and therapeutics areas.

Early Stage

Formulation Development

Preclinical Stage

Clinical Stage

Oncology

Rare diseases

Metabolic disorders

Transplants

Nutraceuticals

We have collaborators and printers around the world